Airtech Advanced Materials Group and Additive Engineering Solutions Partner to Grow Large Format Additive Manufacturing Applications

March 19, 2024

SPRINGFIELD, TN & AKRON, OH – March 11, 2024 : Airtech Advanced Materials Group, the industry le

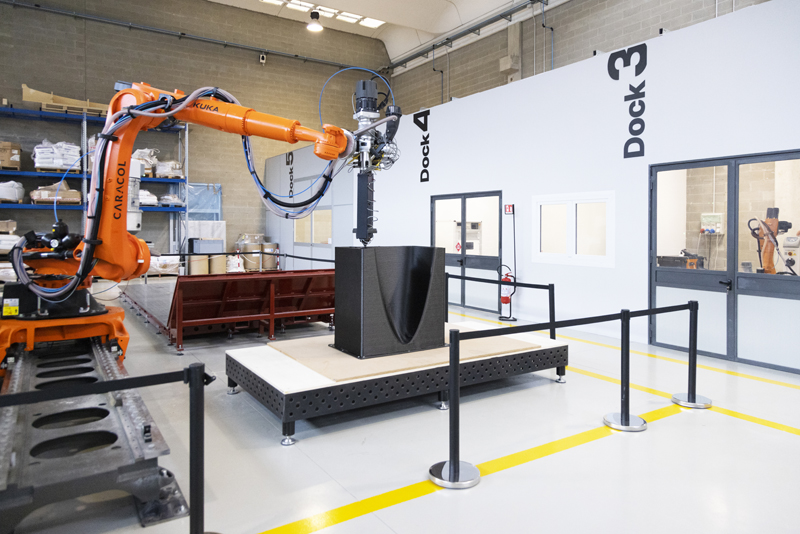

Airtech And Caracol Announce Their Partnership To Grow The LFAM Market With Dahltram® Resins And HERON AM Technology

March 5, 2024

HUNTINGTON BEACH, CA – March 06, 2024: Airtech Advanced Materials Group announces its strategic part

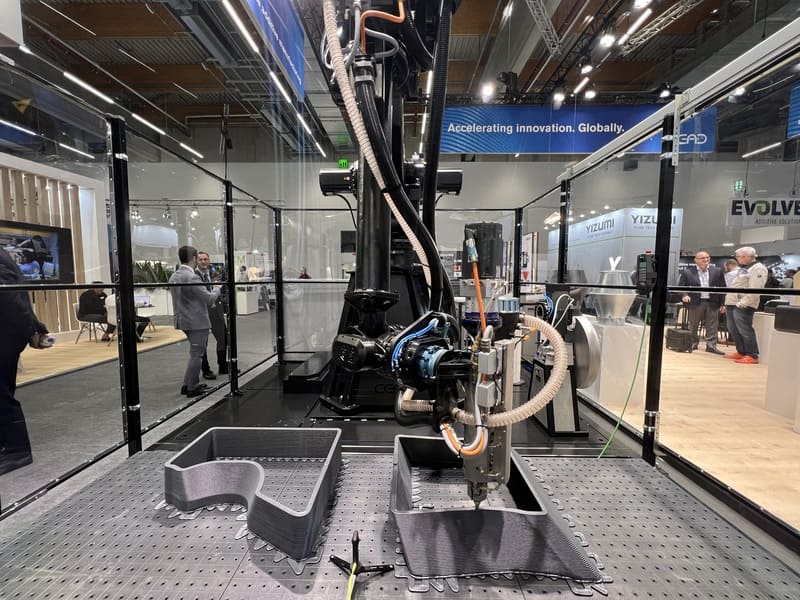

Airtech Redefines Large-Scale 3D Printing with Sustainable Dahltram® T-100GF Resin Debut at Formnext 2023

November 8, 2023

HUNTINGTON BEACH, CA – November 08, 2023: Airtech Advanced Materials Group is proud to announce the

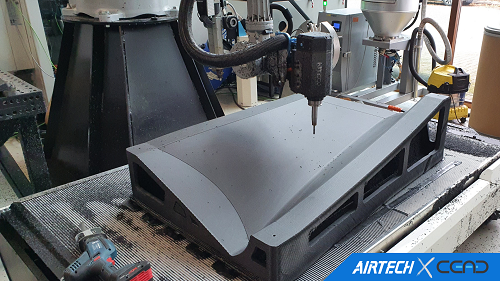

Airtech Advanced Materials Group Unveils Game-Changing Partnership with CEAD

November 2, 2023

Cutting-edge 3d Printing Technology To Revolutionize Precision ManufacturingHUNTINGTON BEACH, CA – N

Airtech Advanced Materials Group Celebrates 50th Anniversary with a New Location in India

May 15, 2023

HUNTINGTON BEACH, CA – May 15, 2023: Airtech Advanced Materials Group, a leading provider of innovat

Tygavac Advanced Materials Announces Name Change to Airtech Advanced Materials UK

November 1, 2022

CHADDERTON, UK – November 01, 2022: Airtech Advanced Materials Group, the largest privately owned manufacturer of vac

Airtech 3D Printed Composite Tooling Enables Legendary Brumos Racing to Take on Pikes Peak 100th Running

June 22, 2022

HUNTINGTON BEACH, CA – June 22, 2022: Airtech Advanced Materials Group, a leading manufacturer of co

Meet us at JEC World #G39 & #E32, Hall 5!

April 22, 2022

This year we have split into 2 booths to offer the best experience and meet visitors in industry-dedicated spaces.

Mitsubishi Gas Chemical America Announces Airtech Distribution for NEXX Technologies

March 24, 2022

NEW YORK, March 24th, 2022 - Mitsubishi Gas Chemical (MGC) announced Airtech Internationa

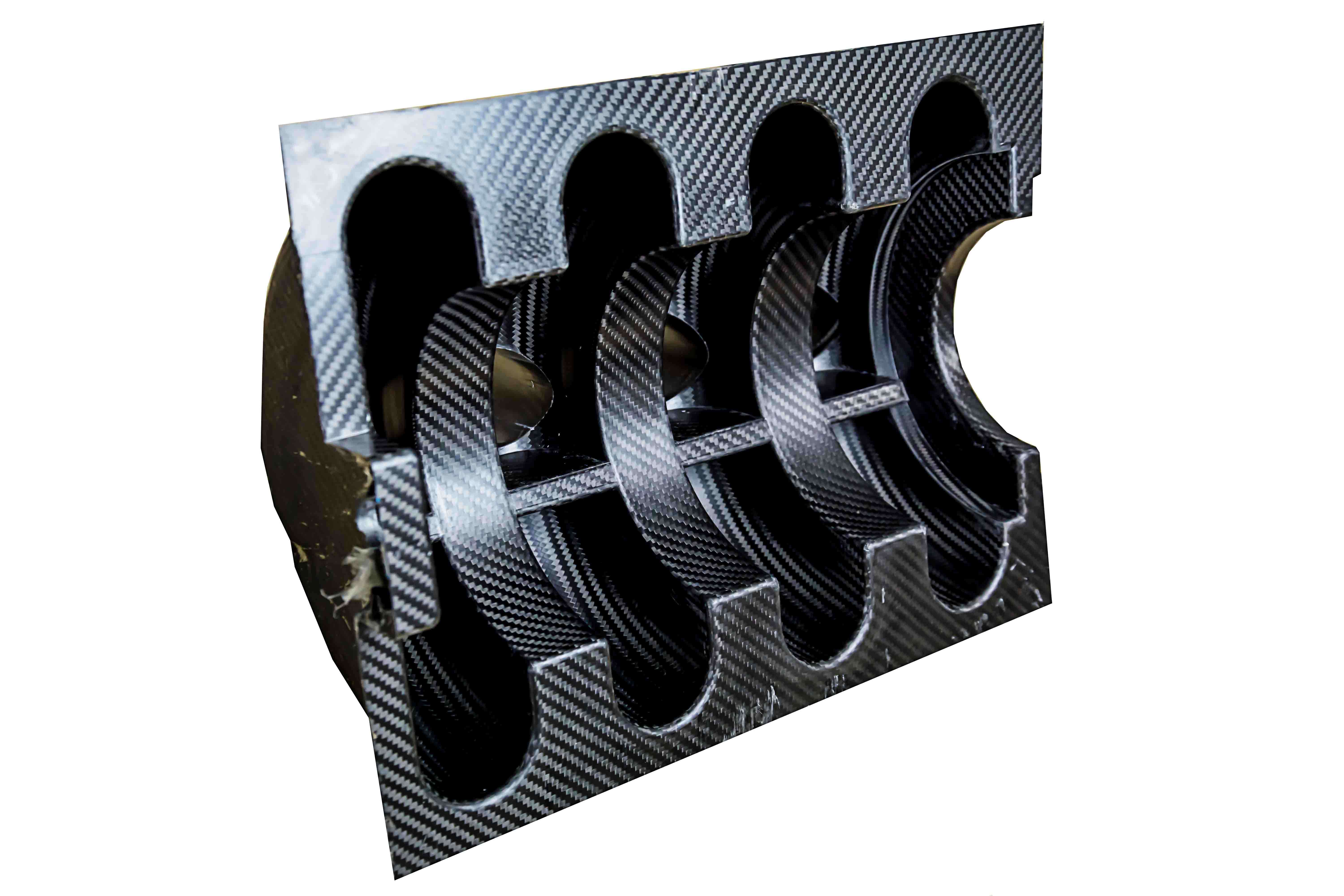

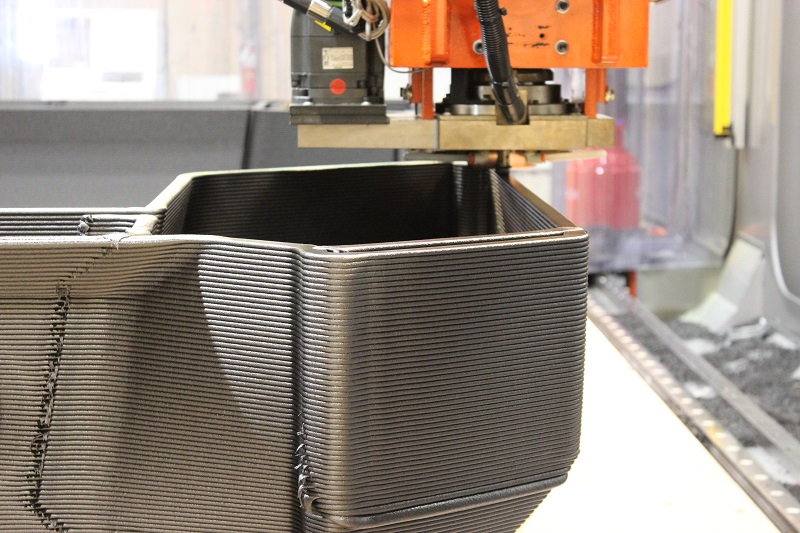

Airtech’s Dahltram® Resins Qualified For Use On All CEAD AM Flexbot Platforms

November 18, 2021

Airtech Advanced Materials Group has been extruding and compounding resins for nearly 50 years and has expanded its o

Airtech’s Dahltram® Resins Approved For Use On All Thermwood LSAM 3D Printers

September 14, 2021

Airtech Advanced Materials Group has been extruding and compounding resins for nearly 50 years and has expanded its o

Airtech’s Dahltram® Resins Approved For Use On All Pellet Fed Titan Robotics Atlas Printers

July 26, 2021

Airtech Advanced Materials Group has been extruding and compounding resins for nearly 50 years and has expanded its o

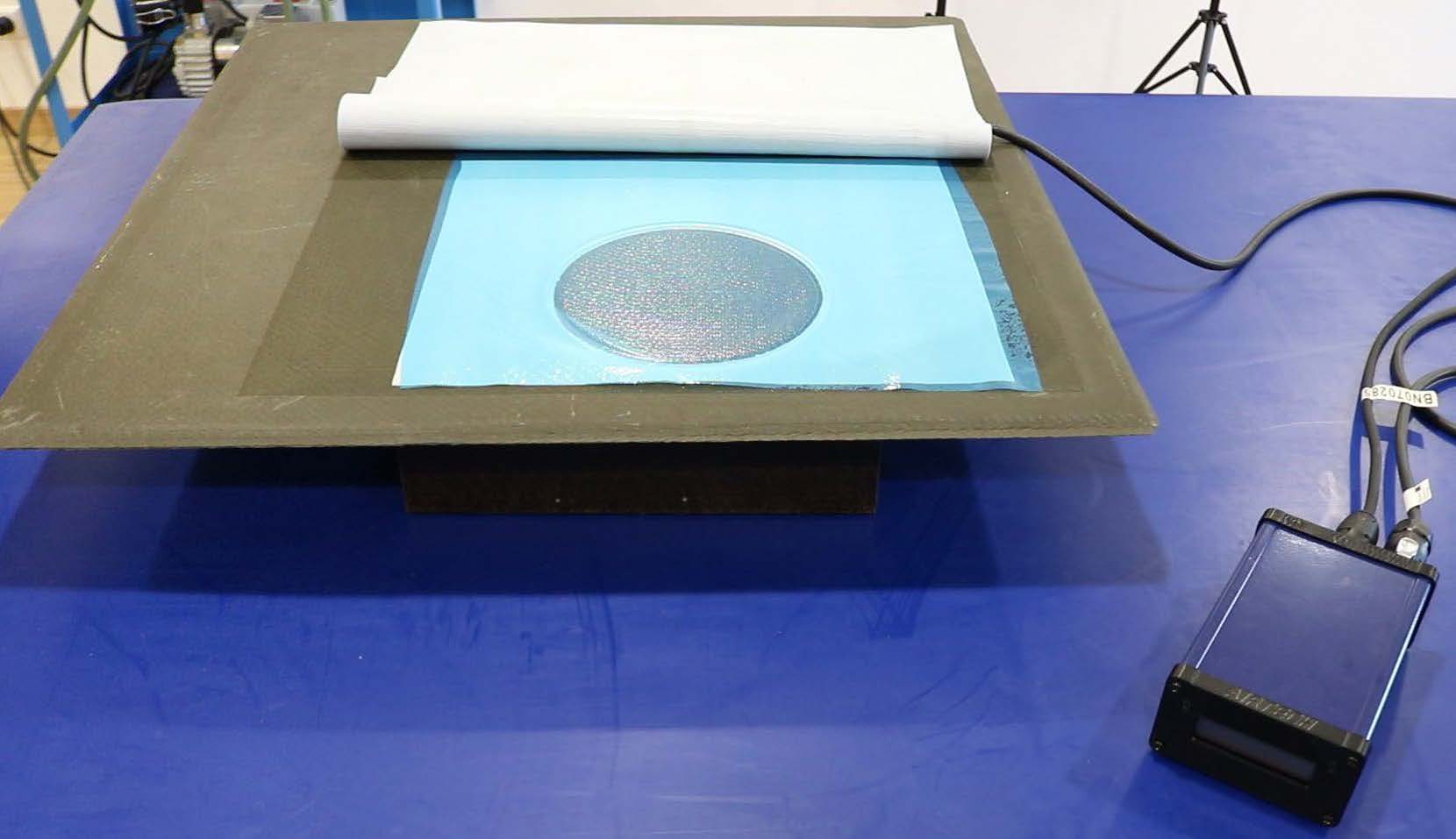

Heat-Tech® Z-1 Flexible heating blankets for composites repair & manufacture

June 29, 2021

The Heat-Tech® Z-1 is a single-zone easy-to-use mobile heating element system.

3D Printing Resins Help Deliver Advanced Manufactured Composite Tooling for Competitive Motorsports Vehicles

June 23, 2021

BBi Autosport returns to Pikes Peak for the 99th running of America’s second oldest race, the Pikes Peak Internationa

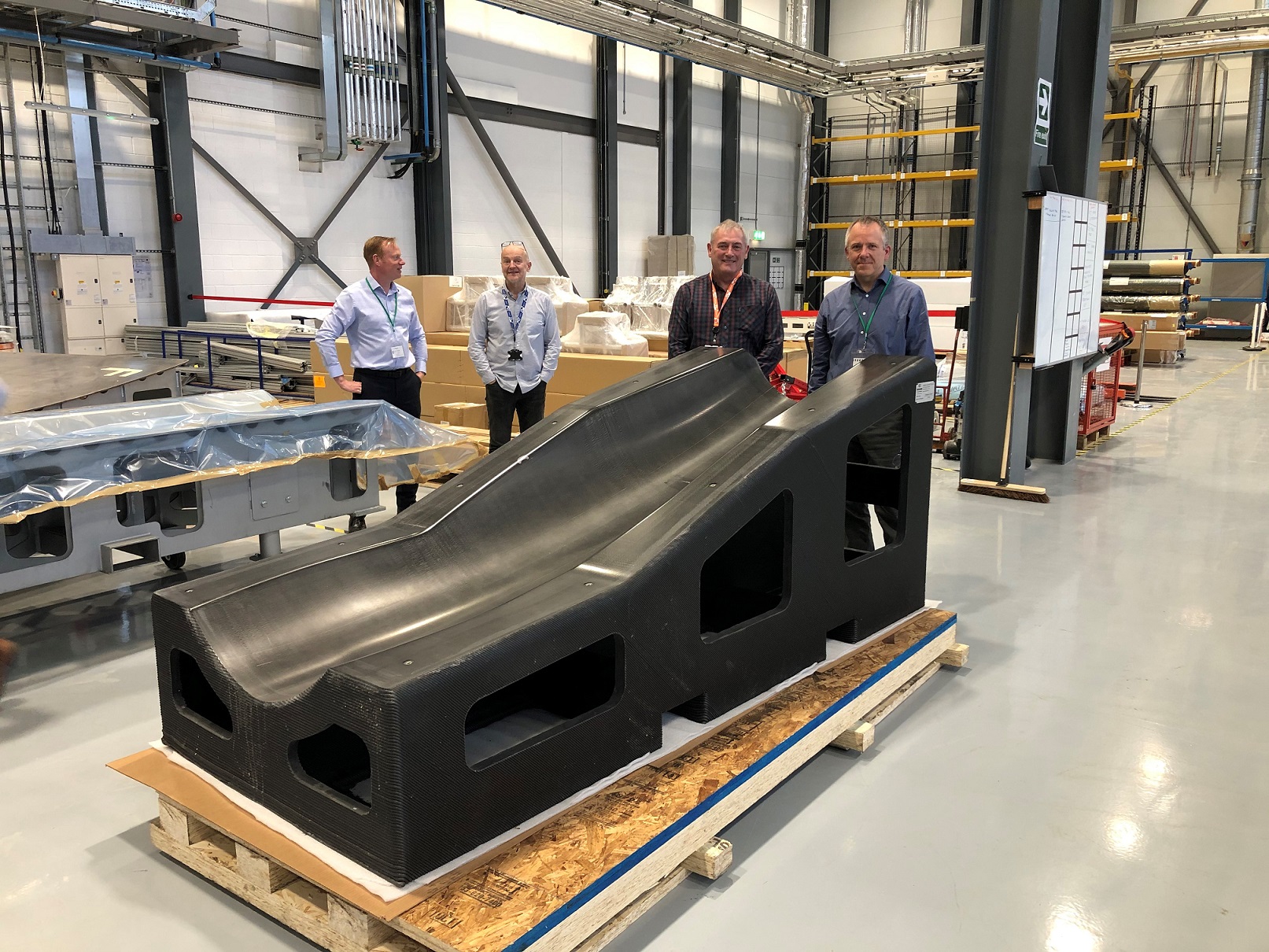

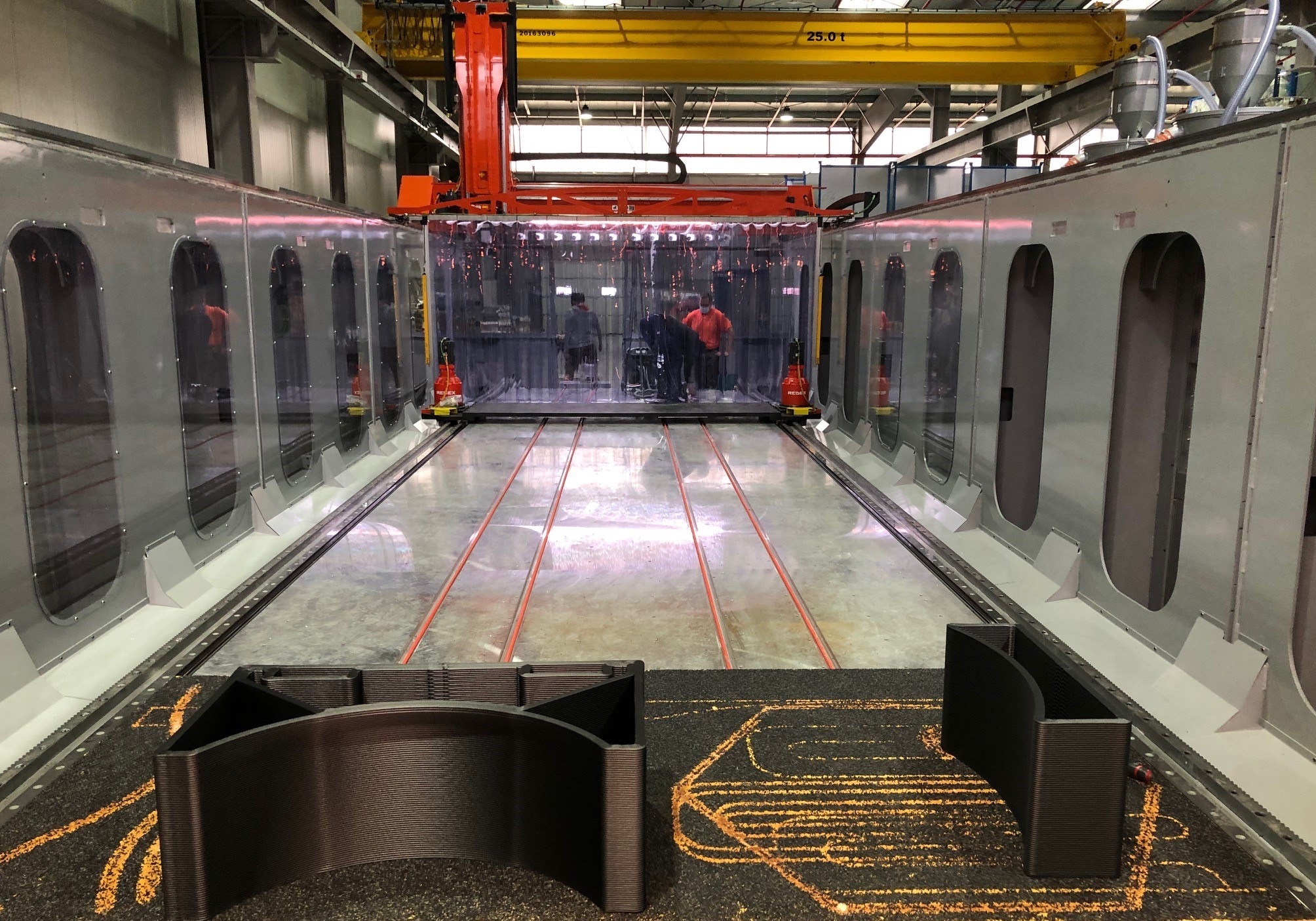

3D Printed Resin Helps Deliver Advanced Manufacturing for the UK Combat Air Sector

May 20, 2021

BAE Systems is using large scale 3D printing to produce high temperature mould tooling utilising Airtech Dahltram® I-

Airtech at JEC Connect 2021

May 12, 2021

We are delighted to be joining JEC Group for an exciting all-new digital event series for the composites community at

Airtech Advanced Materials Group confirms expansion of LARGE SCALE ADDITIVE MANUFACTURING activity, with new European operation in Luxembourg

November 16, 2020

Airtech Advanced Materials Group announced during Formnext Connect 2020, the installation of its second state-of-the-

Discover Airtech’s New Brochures

November 5, 2020

The Airtech product range provides a one-stop-shop for vacuum bagging materials required in d

Airtech Recipient of SAMPE 2020 Organizational Excellence Award

August 11, 2020

Airtech International, Inc is pleased to announce it has been recognised as a winner of the SAMPE 2020 Organizational

Categories

About

We are professional and reliable provider since we offer customers the most powerful and beautiful themes. Besides, we always catch the latest technology and adapt to follow world’s new trends to deliver the best themes to the market.

Featured Posts

Contact info

Corporate Headquarters

-

Address: 5700 Skylab Road,

Huntington Beach, CA 92647

United States -

Phone: +1 714 899 8100